070 51 51 50 +38670 51 51 50 All days of the year from 8:00 a.m. to 7:00 p.m.

Email info@tisto.eu

Address

-

ToolsPopular

ToolsPopular

-

Light construction machinery

Light construction machinery

-

Electric wire tools

Electric wire tools

-

Power cordless tool

Power cordless tool

-

Accessories for power tools

Accessories for power tools

-

PumpsNew

PumpsNew

-

Heating, cooling and solar technology

Heating, cooling and solar technology

-

Battery products

Battery products

-

Charging products

Charging products

-

Photovoltaics

Photovoltaics

-

Inverters

Inverters

-

Electromobility

Electromobility

-

Hand tool

Hand tool

-

Security and health at work

Security and health at work

-

Home and garden tools

Home and garden tools

-

Cosmetic appliances

Cosmetic appliances

-

Building materials

Building materials

-

Garden machines and tools

Garden machines and tools

-

Measuring techniqueBest selling

Measuring techniqueBest selling

-

Microscopy and astronomy

Microscopy and astronomy

-

Firefighting equipmentTop

Firefighting equipmentTop

-

Farm machinery

Farm machinery

-

Office equipment and computers

Office equipment and computers

-

Sanitary ware

Sanitary ware

-

Pallets

Pallets

-

Rental

Rental

-

All categories A complete list of all categories in your online store

All categories A complete list of all categories in your online store

Heating installations

PERT is one of the key components of Home system. Based on pipes and press fittings and offered in diameters ranging from 14 to 75mm, it applies to broad spectrum of heating systems (max. 95 deg. C).

PERT pipes and fittings are perfectly suited for heating installations in every type of buildings

Key advantages of PERT heating installations:

- durability estimated lifespan of min. 50 years

- energy - saving due to low pressure losses and low thermal conductivity

- flexibility with no shape remembrance multilayer pipes are more flexible than any other known

- Translate

- pipes and can be bended without any supports. Bending radius is on the level 4-5 x Dn

- thermal stability (0.025mm/mK) very low thermal expansion coefficient (0.025mm/mK), is comparable with values characteristic for steel or copper pipes

- total impermeability of connections

- possibility of making connection with any other pipe by using threaded couplings

- low weight

- resistance for oxygen diffusion

Types of installations

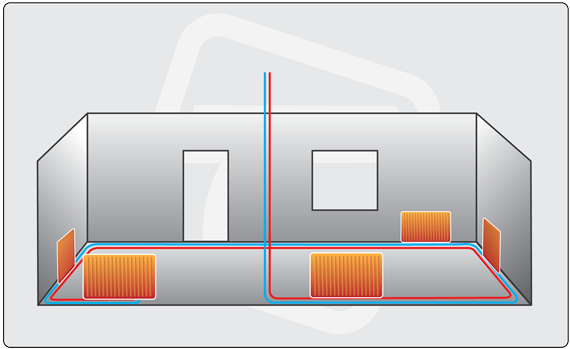

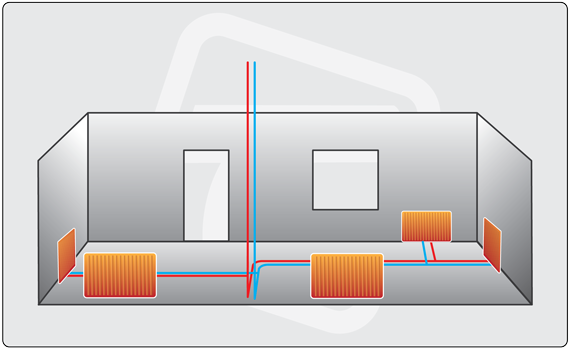

Tee based arrangements

Heaters are supplied from the main line by branches leading to tees mounted on them. Supply lines are usually located in the floor or on the wall in following arrangements:

Circuit type - heating medium is distributed along the walls where heaters are mounted. This allows the use of masking bars, making this type of system ideal for renovation. Relatively large demand for pipe and the need to go through the construction barriers are the main disadvantages of this arrangement.

Radial type – heating medium is freely distributed from vertical supply line to the heaters without the need of getting through the construction barriers. The pipes are routed from the middle of the room which leads to reduction in their required length.

Tee based arrangements do not give any possibility to replace damaged pipes without forging floors or plaster. Moreover, connecting of additional heaters to the main supply line will gradually decrease the pressure and will cause trouble with flow adjustment on individual plots.

It is the major disadvantage of tee based arrangements in comparison to manifolds.

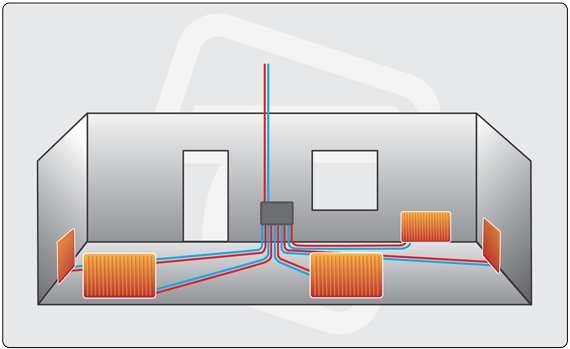

Manifold based arrangements

The ability to supply each radiator with a separate line that runs straight from the manifold is a specific feature of this arrangement.

Summary of qualities:

- ease of adjustment

- ability to make changes in the installation without the need of forging the floor

- lower risk of failure - there are no connections between the radiator and the manifold located in the floor

- no need of investment in expensive tools - only a simple flat wrench is required for manifold based installation

- fast installation – time savings

Within the Tweetop Home system, there are several brass manifolds available - designed for managing from 2 to 12 supply lines, depending on the actual type chosen.

Manifolds should be mounted in special cases, which can be mounted both directly on the plaster as well as countersunk below it. There is enough room in the case to incorporate cutting valves for every single circuit managed by given type of manifold.

Routing

On the installation design stage, it is important to remember about:

- using coverage/protection pipes

- supplying the heaters from manifolds with shortest possible segments of pipes

- increasing the length of pipe for ease of thermal expansion within the installation

- avoiding very sharp turns and long sections of pipes with many turns

- ensuring the possibility of inner pipe replacement

- possibility of Tweetop PERT pipes bending

- marking the placement of pipes under the floor and in the walls which will help to avoid any damage due to drilling

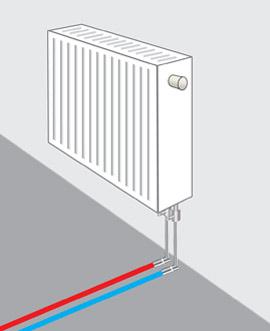

Radiator connections

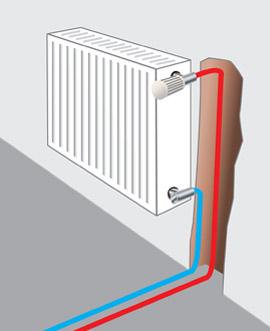

For C type radiators

Connection based on press screw couplings or press coupling - reducers, with utilization of Tweetop PERT pipes advantages allowing for pipe bending radius being equal to 4 times its inner diameter.

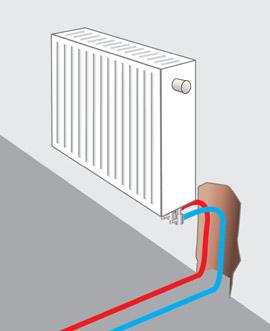

For V type radiators (a)

Connection based on press screw couplings with utilization of Tweetop PERT pipes advantages allowing for pipe bending radius being equal to 4 times its inner diameter.

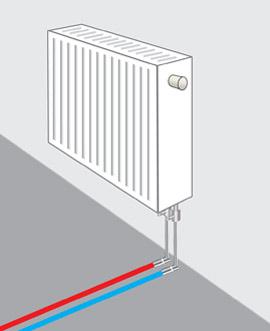

For V type radiators (b)

Connection based on knee with 15mm diameter nickel plated copper pipe.

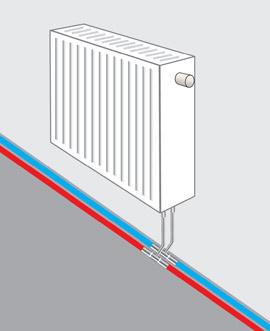

For V type radiators (c)

Connection based on tee with 15mm diameter nickel plated copper pipe.

No posts found

Write a review- For telephone orders, we are available every day of the year from 8:00 to 19:00

- Dunajska cesta 101

- 1000 Ljubljana

- Slovenia EU

- +38670 51 51 50

- info@tisto.eu

© 2009 - 2025 TISTO. We make every effort to publish only verified and correct data; if you find untrue or inappropriate information on our site, please let us know at info@tisto.eu. The photos do not guarantee the properties of the products.