Based on pipes made in special technology, along with a broad range of fitting elements and accessories which make every type of connection possible, PERT is a complete installation solution.

PERT system offer includes pipes and fittings in 16 - 75mm diameters with a set of essential accessories and installation tools dedicated to specific applications of the system.

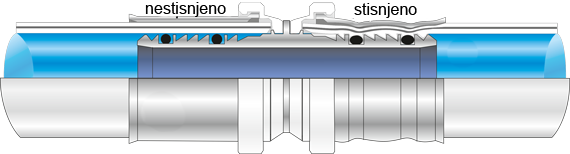

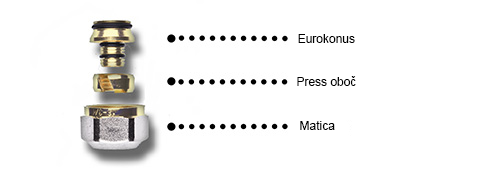

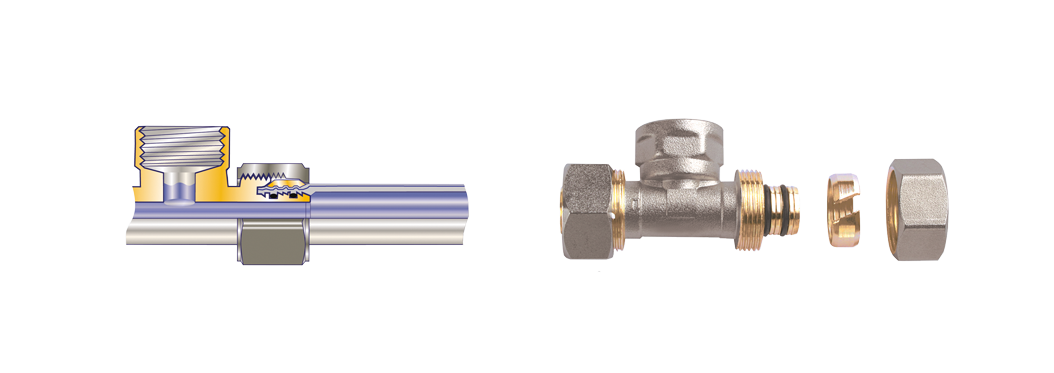

PERT system based on multilayer pipes joined by pressed connections is currently one of the most advanced and innovative solutions available on the market. This is determined by two factors - the construction of the pipes and the connection technology. PERT pipes have a multilayer structure - their core is made from an ultrasonically welded aluminium pipe. After adding two layers of the raised temperature polyethylene (PERT) material to the inside and outside of the aluminium pipe, we obtain a multilayer pipe capable of simultaneous work under the influence of pressure and temperature rated at 10 bar and 95°C. This unique combination of plastic material and the conventional aluminium insert allows PERT pipes to keep the advantages of both, traditional and plastic pipes while eliminating their disadvantages.