070 51 51 50 +38670 51 51 50 All days of the year from 8:00 a.m. to 7:00 p.m.

Email info@tisto.eu

Address

-

ToolsPopular

ToolsPopular

-

Light construction machinery

Light construction machinery

-

Electric wire tools

Electric wire tools

-

Power cordless tool

Power cordless tool

-

Accessories for power tools

Accessories for power tools

-

PumpsNew

PumpsNew

-

Heating, cooling and solar technology

Heating, cooling and solar technology

-

Battery products

Battery products

-

Charging products

Charging products

-

Photovoltaics

Photovoltaics

-

Inverters

Inverters

-

Electromobility

Electromobility

-

Hand tool

Hand tool

-

Security and health at work

Security and health at work

-

Home and garden tools

Home and garden tools

-

Cosmetic appliances

Cosmetic appliances

-

Building materials

Building materials

-

Garden machines and tools

Garden machines and tools

-

Measuring techniqueBest selling

Measuring techniqueBest selling

-

Microscopy and astronomy

Microscopy and astronomy

-

Firefighting equipmentTop

Firefighting equipmentTop

-

Farm machinery

Farm machinery

-

Office equipment and computers

Office equipment and computers

-

Sanitary ware

Sanitary ware

-

Pallets

Pallets

-

Rental

Rental

-

All categories

A complete list of all categories in your online store

All categories

A complete list of all categories in your online store

Brushless or traditional motor - what are the differences, what are the advantages of induction motors.

Brushless motors - comparison to brush motors

The manufacturers' offer includes twin designs that differ in the type of engine used. What is a brush motor and what are the advantages of a brushless motor? Is a brushless motor more efficient? We will try to answer these and other questions in this post.

Before we take a closer look at the brushless motor, let's briefly check what the traditional motor is characterized by.

What is a brush motor, or commutator motor

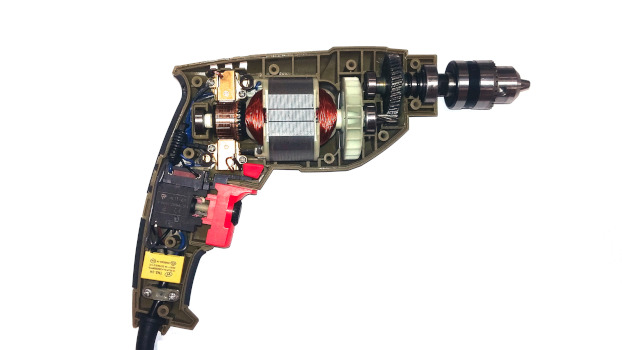

This is the basic type of electric motors used in portable electrical devices such as power tools. Thanks to its simple structure, it is easily repaired, among other things. Briefly, in its design, the brush motor includes:

- electrographite brushes - responsible for supplying power to the commutator

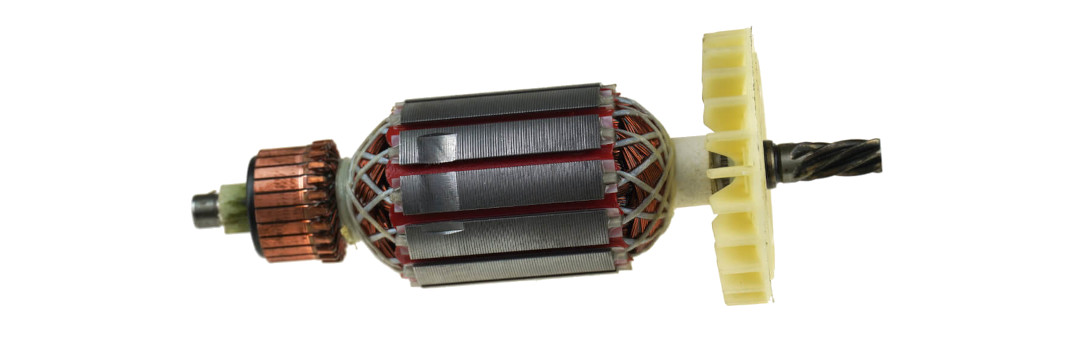

- rotor - a rotating element mounted on an axis led out to the outside. It is inside the magnetic field generated by magnets in the stator. It is made of several coils arranged angularly to each other.

- stator - a fixed element, constituting the motor housing. It surrounds the rotor and contains permanent magnets with opposite poles directed towards each other.

- commutator - located on the rotor shaft, is responsible for changing the direction of the current. The commutator is a series of copper plates between which there is an insulator. The plates are connected to the individual windings and are arranged along the entire circumference of the commutator.

- winding - it is a wire that is wound around the rotor, often aluminum or preferably copper

As a result of starting the device (switching on the power), the electrographite brushes slide on the surface of the commutator plates, supplying power to it and to the motor winding. As a result of the flowing current, a magnetic field is created, which reacts to the magnets placed in the stator. This is how the force is created which is responsible for the rotation of the rotor, and this force drives the gear with the spindle of the device through the axis located in its center. The spindle ends with a handle, e.g. a drill chuck (screwdrivers, drills, impact drills), an SDS head (hammer drills) or an M14 thread (in the case of angle grinders), which allows the installation of appropriate working tips such as bits, drills or cutting discs.

What is a brushless motor?

The brushless motor, as the name suggests, does not contain electrographite brushes, but this is not only its only difference. The simplest construction of a brushless motor consists of windings, which are 3 coils connected in a star system. More advanced solutions may have more coils and different connection systems. The coils are placed on a steel core. Its task is to focus the magnetic flux created by the current flow through the coils. The generated magnetic field makes it possible to change the position of the rotor. In short - by alternating the supply of the coils, there is a continuous change within the generated magnetic field, which translates into a spinning motion of the rotor

The advantages of a brushless motor

In addition to a different structure, the brushless motor has gained many advantages thanks to the elimination of electrographite brushes. Even such a prosaic thing as no need to replace them translates into the comfort of use. Not all devices have quick access to brushes. Usually, it is necessary to disassemble the housing of the device, which is for people who are not experiencedin the arcana of electronics repair can be quite a challenge. Another thing is often the problem with access to the appropriate electrographite brushes - especially in devices that are several years old and have been withdrawn from the manufacturer's offer. And in small commutator motors, the manufacturer often did not provide for their replacement, which results in the need to replace the entire drive unit. The elimination of carbon brushes also means greater durability and reliability in relation to brushed motors. As a result of the sliding of the brushes on the surface of the commutator and the nature of the user's work, the brushes may wear unevenly, which translates into increased wear of the commutator and rotor, shortening the life of these parts. Due to the elimination of sparking in devices with a brushless motor, their use in environments with an increased risk of ignition is less risky than using brush motor tools. Brushless motors reach smaller dimensions, which translates into a more compact structure, better suited to the user's needs, and the limited number of parts results in a lower failure rate than in traditional brushed motors.

Thanks to the electronically controlled commutator, it is possible to achieve high efficiency in a wide range of rotational speeds, and in the event of a high load, it is easier to maintain operating parameters than in brush solutions.

In addition, the use of a brushless motor means quieter operation and higher energy efficiency. It results from the fact that brushless motors have a lower demand for electricity than their brush counterparts. In the case of devices powered from a battery, this translates into the time of operation on a single charge or allows the use of a smaller battery capacity without losing the efficiency of the device. This, in turn, may contribute to a lower weight of the device.

Another important advantage is better heat dissipation from the engine, thanks to which the manufacturer can use more hermetic housings increasing the IP protection index, e.g. against increased moisture and larger water splashes. It also provides greater long-term load capacity where the traditional brushed motor can fail due to overheating.

How to recognize that the device has a brushless motor?

With standard products, unfortunately, we will rely on ourselves or the seller's knowledge. What should attract our attention is a more tight, smaller housing and possible additional markings on the product. DEDRA in its line of devices from the DEDRA SAS + ALL series, tools containing a brushless motor are distinguished by a special metallized logo and a "brushless motor" print, thus ensuring that we are buying a product with a brushless motor.

In summary, devices equipped with a brushless motor have a number of advantages resulting from the design and type of motor used. Starting from greater efficiency, work safety, to maintenance-free resulting from the elimination of consumable parts such as electrographite brushes. The advantages will be appreciated by all those who are professionally youuse electrical appliances. However, DIY amateurs should also keep this type of tool in mind, because the comfort of working with a tool with a brushless motor is much greater ("greater reserve" of power, more compact size, no sparking, maintenance-free).

Unfortunately, the components required in the production of this type of motors are still relatively expensive, which translates into the final price of the product, and thus the availability of an induction motor solution in the offered devices, but the advantages of such a motor structure compensate for its higher price.

- Borstelloze motoren

- borstelmotoren

- Borstlösa motorer

- borstmotorer

- Brezkrtačni motorji

- brush motors

- Brushless motors

- Bürstenlose Motoren

- Bürstenmotoren

- Børsteløse motorer

- børstemotorer

- kartáčovými motory

- Kefe nélküli motorok

- kefés motorokkal

- krtačnimi motorji

- les moteurs à balais

- los motores con escobillas

- Moteurs sans balais

- Motores sin escobillas

- Motori bez četkica

- Motori brushless

- motorima s četkicama

- Silniki bezszczotkowe

- silników szczotkowych

- Střídavé motory

- κινητήρες βούρτσας

- Κινητήρες χωρίς ψήκτρες

Giuseppe 02/01/2024, 11:27

Dovendo acquistare un utendile agricolo"tagliasiepi" con motore Brushless da 450 Wh ed essendo alimentato da una batteria

Li-Ion da 21v 5Ah quanto dura la carica della batteria in condizioni di test(senza attriti di lavoro/temperarura ecc). Il calcolo è uguale come per i motori a grafite(legge di Ohm)

Distinti saluti

- For telephone orders, we are available every day of the year from 8:00 to 19:00

- Dunajska cesta 101

- 1000 Ljubljana

- Slovenia EU

- +38670 51 51 50

- info@tisto.eu

© 2009 - 2025 TISTO. We make every effort to publish only verified and correct data; if you find untrue or inappropriate information on our site, please let us know at info@tisto.eu. The photos do not guarantee the properties of the products.